Building an identity for yourself as an artist, designer, author, or photographer is a challenge. Not only are you judged by the creativity and originality of your work, but you may also be judged by how creatively and professionally you present yourself.

Whenever you interact with fans and customers online (through your website, blog, and social media) and in real life (at art fairs, book signings, or photo exhibitions), every interaction adds up to make a memorable impression. (Marketers call these interactions ‘touchpoints.’)

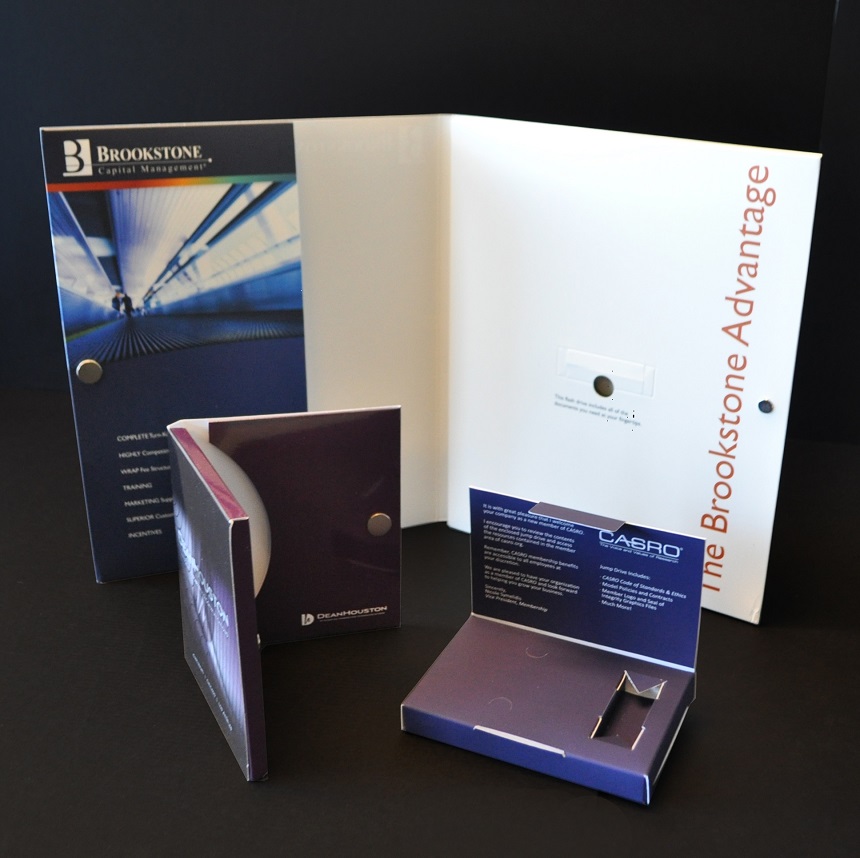

How you package your products also speaks volumes about your commitment to your craft. Is your packaging bland, boring, and cheap-looking? Or do customers feel like they are receiving a wonderful gift to themselves when they receive a box in the mail from you.

One company that can help you make a consistently first-class impression is ThePaperWorker.com.

Through ThePaperWorker.com, you can use online templates and digital design tools to order as many boxes as need, whether it’s 5, 10, 20, or 100, or anywhere in between. At the same time, you can order presentation folders, tabletop display signs, or banners that you can take with you to events where you will be selling your works in person.

“Our packaging has detail and dimension, we have created ways to make the process easy and straightforward for our customers, regardless of their knowledge of custom packaging,” said Todd Anson, president of ThePaperWorker.com “Pricing is broken down simply by quantity, product descriptions are detailed, templates are provided in PDF/EPS formats, and 3D PDFs are available to view on every product.”

If you prefer to have an experienced package designer create your packaging graphics or review the designs you have uploaded, you can request those services on ThePaperWorker.com website.

Expertise from The Colad Group

All of the products available through ThePaperWorker.com reflect the deep expertise of The Colad Group, a company that has been developing custom presentation materials and packaging for more than 60 years.

Until five or six years ago, The Colad Group could only serve customers who needed at least 250 boxes. That’s because their printing processes required making plates for each color of ink and dies for cutting and scoring the box designs on a die-cutting press.

Digital printing and cutting technology has changed all that. Orders submitted through ThePaperWorker.com are produced on automated digital presses and finishing equipment. Full-color photographic images can easily be printed on the boxes without the extra time and costs associated traditional offset printing.

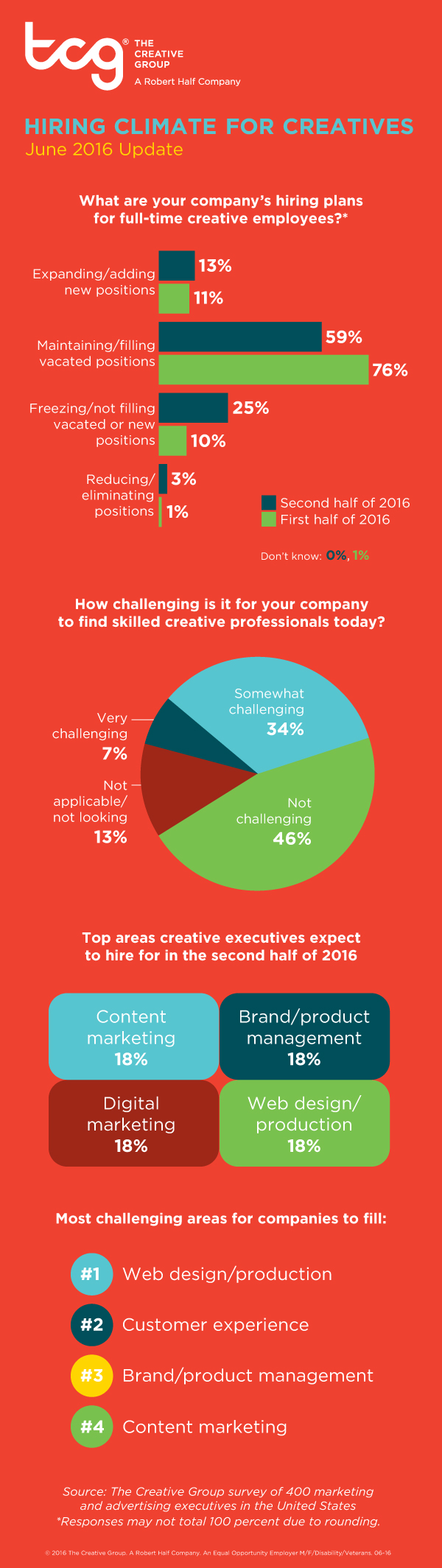

For more information about the benefits of custom packaging, see the infographic posted on The Colad Group blog.

More about The Colad Group’s commitment to using and recycling environmentally friendly packaging materials, is available on their website.