Can fine-art photographers find ways to incorporate 3D printing in their work? Yes, according to Sandra Canning, an award-winning South Florida-based fine art photographer. On September 5, she exhibited four 3-D printed photographic lithopanes alongside three of her traditional 2D prints. The event was part of an artist’s night gathering at the LMNT fine-art collaboration and event space in Miami.

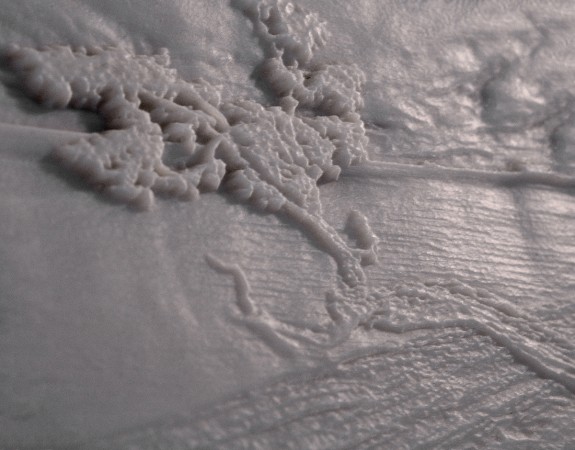

Lithopanes look like a bas relief to the naked eye, but when the lithopane is backlit, the picture is revealed. Lithopanes were made from translucent porcelain when the art form was popular in the 1800s. Canning’s exhibit at LMNT demonstrated how 3D printing can be used to convert fine-art photos in the 21st-century lithopanes.

Canning created the lithopanes in collaboration with Prototyping Solutions Inc., one of the largest resellers of Stratasys 3D Printers in North America. Serving businesses in Alabama, Arkansas, Georgia, Florida, Louisiana, Mississippi, North Carolina, South Carolina, and Tennessee, the staff at Prototyping Solutions helps people choose the right printer, material part, and solution for any 3D printing need.

The exhibit was entitled “Photography’s Past, Present, and Future as Expressed Through 3D Printing” and represented the inaugural get together of “The Art of 3D Printing” Meetup Group that Canning founded for Miami-area artists. Along with Canning’s 3D printed photography, the September 5th event featured a TED-style talk by engineer/3D-printing pioneer Werner Blumenthal, and “3D-printed selfies” produced by FORGE, a 3D-printing studio based in Jacksonville, Florida.

Canning started The Art of 3D Printing Meetup Group in her quest to learn more about 3D printing and encourage its use in the arts. She recognized that while 3D printing is revolutionizing every aspect of the creative arts, “Photographers have not had much involvement in this movement.” She came across 3D printed lithopanes in her quest to find applications for 3D printing for photographers.

“3D printing was one of those things that had been in my peripheral vision but I never felt any personal connection,” explains Canning. “In May or June of 2014, I was looking for something unique to do with my pictures.” When she started researching 3D printing, she was blown away by the impossible structures being printed in fashion, sculpture, jewelry, architecture, and even bioprinting: “I knew that I was looking at something that was going to change everyday life — not just the creative arts.”

She felt left out when she first tried to find applications of 3D printing for fine-art photographers. Then, she ran across some 3D-printed lithopanes of Yoda and cats, and says, “At that moment I got the bug to create fine-art quality lithopanes inspired by the ones from the 1800s.”

Canning didn’t believe the first 3D printed lithopanes she saw were gallery worthy, so she sought out different services, materials, and methods that would produce a fine-art result.

Prototyping Solutions, Inc in Birmingham, Alabama proved to be the perfect partner for this marriage of art and technology. The team of experts, including Vince Denino and Rixey Kelly, consulted with Canning to produce the parts well within the assigned budget and ahead of schedule.

The lithophanes of Canning’s photos were printed at 16 micron layer height in Vero White on a Stratasys Objet260 Connex 3D printer. Each part took around 30 to 45 minutes to build.

“This 3D printing project has been a great joy to be a part of because it was targeted to a different audience than we are used to,” said Rixey Kelly, Service Engineer at Prototyping Solutions. He said the widgets and gizmos they typically print are artistic enough in their design and function but don’t do much for the soul: “The lithophanes, much like widgets, are ideas that can be printed and then held in your hand. But these uniquely depict a place and moment in time.”

Canning collaborated with a local maker John McNulty (makerssquare.com) and his partner to create the backlit frames.

Art of 3D Printing Meetup Group

During the 3D Photo Art exhibit at LMNT, Canning said many visitors said they had never seen anything like it before. She says, “I think most people were surprised that you could 3D print a photo in this way.” They asked plenty of questions about the process, the smoothness of the surface, the cost, and the learning curve.

Canning founded the Meetup group as a way to learn and grow with other who are interested in The Art of 3D Printing. A second event she hosted demonstrated 3D scanning for creating 3D selfies and featured equipment supplied by 3D Systems.

So what’s next for this accomplished photographer who wants to explore the potential of 3D printing?

“Since my journey to learn 3D printing began, I have had a clear picture of the ultimate 3D printed photographic lithopane,” says Sandra. “I am still perfecting those for a future exhibit.” She also has some ideas for 3D printed scultpures and jewelry.

LINKS

Meetup Group: Art of 3D Printing