The scope of the International CES conference and expo extends well beyond everyday electronics such as TVs, tablets, audio systems, cameras, and gadgets.

The scope of the International CES conference and expo extends well beyond everyday electronics such as TVs, tablets, audio systems, cameras, and gadgets.

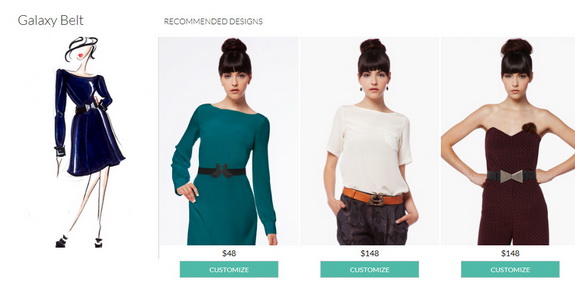

The 2014 International CES (January 7-10) in Las Vegas will showcase how connected technologies are changing the way we run our homes, drive our cars, educate our children, monitor our health, care for the sick, buy things in stores, play games, and watch videos. Tech zones will include areas devoted to robotics, fashionware, fitness technology, digital health innovations, and 3D printing.

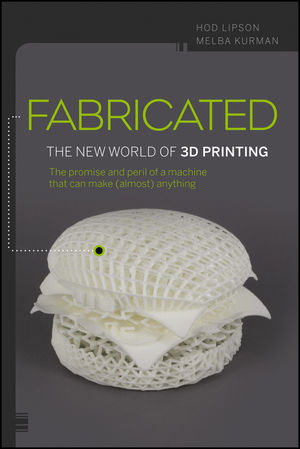

The 3D Printing TechZone will showcase the various additive manufacturing processes that are being used in making prototypes in the medical, aerospace, engineering, and automotive industries as well as the more compact 3D printers that are making the process more accessible to makers and consumers.

A Conference Track entitled, “Don’t Believe the Hype? 3D Printing Uncovered” is being organized by experts from TCT Magazine and Personalize.

A Conference Track entitled, “Don’t Believe the Hype? 3D Printing Uncovered” is being organized by experts from TCT Magazine and Personalize.

Personalize is a web portal that delivers 3D printing news and printable designs to consumers. TCT Magazine is a leading source of business intelligence on industrial 3D printing. They have been covering the topic for more than 20 years. The editors of TCT magazine note that “3D printing is an overnight sensation that has been around for 30 years. Consisting of tens of technologies processing hundreds of materials, there’s more to it than meets they eye.”

The 3D Printing Conference track at CES will bring together thought leaders, 3D printer manufacturers, champions of 3D printing-related businesses models, and industrial super-users of 3D printing processes.

Speakers will include:

- Avi Reichental, CEO of the 3D printing equipment manufacturer 3D Systems,

- Clement Moreau, CEO of the Sculpteo 3D printing service, and

- TCT columnist and technology consultant Todd Grimm.

Other Programs of Interest to Creators

Sometimes, the disruptive impact of emerging technologies can difficult to predict. Many of the conference sessions are less about the technologies, and more about the types of changes they might bring.

For example, one session will focus on how Hollywood is being affected by the world of always-connected, always-on media and the ability to watch video whenever and wherever we want. Another session will examine how mobile photography on smartphones and tablets has affected photography-related businesses.

A session entitled “The Roar of the Crowd” will examine how crowdfunding through sites such as Kickstarter to deviantArt is changing how content is funded, created, and curated.

Other session titles include:

- Merging Content with New Technologies

- The Digital Copyright Debate: What Needs to Change?

- YouTube: Unlocking the Power of Programming, Premium Content, and Advertising

- The Future of Gaming

- The Smartphone/Tablet Economy

- The Multiscreen Universe

- Redefining the Relationship Between the Consumer, Advertising, and Media Platforms

- The State of Digital Music

- Impact of the 3D Printing Revolution

- The Power of Co-Creation and the Maker Revolution

International CES

The International CES is the world’s gathering place for all who thrive on the business of consumer technologies. Held in Las Vegas every year, it has served as the proving ground for innovators and breakthrough technologies for more than 40 years—the global stage where next-generation innovations are introduced to the marketplace.

CES showcases more than 3,200 exhibitors, including manufacturers, developers and suppliers of consumer technology hardware, content, technology delivery systems and more; a conference program with more than 300 sessions; and more than 152,000 attendees from more than 150 countries.

LINKS