If you use additive manufacturing, 3D printing, or 3D imaging technologies to create works of art, here is an opportunity to get exposure and recognition for your work.

The Society of Manufacturing Engineers (SME) is seeking submissions for artwork that will be displayed in the Contemporary Art Gallery during the RAPID Additive Manufacturing Solutions Conference and Exposition to be held at the David L. Lawrence Convention Center in Pittsburgh, Pennsylvania, June 10-13, 2013. The deadline for submitting entries is March 4.

“RAPID presents artists familiar with design software and additive manufacturing processes the opportunity to display their work to an appreciative audience, while providing traditional artists the opportunity to explore this new medium and participate in the 3D printing industry,” said SME business development manager Gary Mikola.

To enter, submit renderings in JPG file format along with your credentials and a list of the processes used to create the artwork. Event advisors will select the submissions that will be displayed in the gallery. Preference will be given to artists whose works have already been created using additive technologies. But artists are encouraged to submit works in CAD/STL files because a limited number of entries will be printed by professional additive manufacturing service providers.

All artwork in final form must be durable and stable for display on a 2-foot square surface pedestal. Artwork will be prominently displayed on the RAPID show floor. Artists will receive publicity and promotion in the form of press releases, listings in the printed show directory, online visibility in the RAPID Contemporary Art eGallery and social media marketing.

“This innovative artistic medium will provide an economic boon to the artists themselves, as well as to the additive manufacturing industry as a whole,” Mikola added. Since SME introduced their Contemporary Art Gallery in 2010, more than 50 works of art have been displayed.

Background

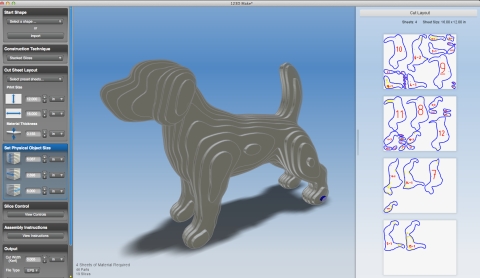

Artists are using additive manufacturing, 3D printing and 3D imaging technologies to create dimensional art with complex patterns and geometries. First, they use CAD software to create digital models of their work. The CAD files are converted into a 3D-printable STL file format that is then transferred to a 3D printing / additive manufacturing machine.

The machine outputs different materials onto a platform, building cross sections one layer at a time. Each layer corresponds with the virtual cross-section of the artists’ CAD file to create the final work of art. (For an example, see the post: Portrait Sculptures Created with 3D Printing )

The RAPID Additive Manufacturing Solutions Conference and Exposition is North America’s definitive event featuring 3D imaging and 3D printing technologies. The expo attracts buyers, sellers and end-users of design, prototyping, tooling and direct digital technologies. RAPID is produced by the Society of Manufacturing Engineers, the premiere source for manufacturing knowledge, education, and networking.

LINKS

RAPID Additive Manufacturing Solutions Conference

What Is Additive Manufacturing?

RELATED POST

Portrait Sculptures Created with 3D Printing